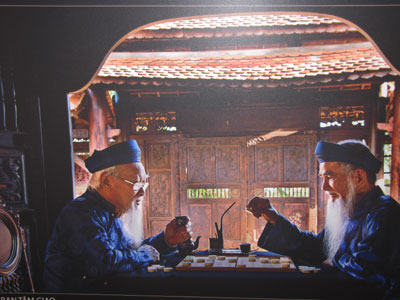

Đăng ký thẻ thành viên và tích điểm

Khi trở thành thành viên bạn sẽ có những quyền lợi nhất định, đảm bảo đáp ứng mọi nhu cầu thiết yếu của khách hàng

Quyền lợi thành viên:

- Ưu tiên hàng đầu về mọi mặt: thông tin sản phẩm, thông tin khuyến mãi và dịch vụ chăm sóc khách hàng ( sinh nhật, ngày lễ và các sự kiện...)

- Cơ hội tham gia những chương trình đặc biệt khác chỉ áp dụng cho thành viên của HaNoi Moment

Chương trình điểm thưởng:

Chương trình bao gồm 4 đối tượng thành viên THÂN THIẾT, BẠC, VÀNG, KIM CƯƠNG với những quyền lợi và mức ưu đãi khác nhau. Mỗi khi thực...

[Xem thêm]